A major milestone for the dairy industry and other food-contact packaging

Montreal, April 22, 2025 – UpSolv (formerly Polystyvert) is proud to announce that it has received a No Objection Letter (NOL) from the U.S. Food and Drug Administration (FDA), confirming that its proprietary secondary recycling process can produce recycled polystyrene (rPS) suitable for direct food-contact applications, including yogurt cups and other packaging formats.

“The FDA’s recognition of our patented dissolution and purification process marks a significant milestone in commercializing high-quality, food-grade recycled HIPS,” said Nicolas Cottenye, Vice President, Research & Development at UpSolv. “With increasing regulatory pressure to include recycled content in packaging, this sends a strong signal to our partners across the dairy value chain: together, we can meet those targets and close the loop.”

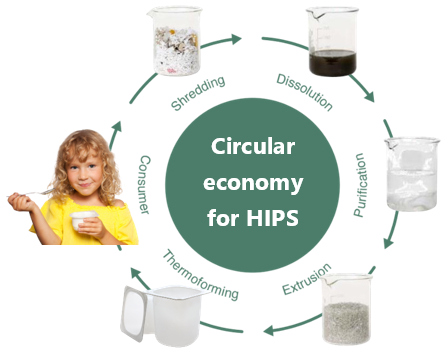

UpSolv’s technology was validated through an initial collaborative project that produced yogurt cups made entirely from polystyrene waste. These cups featured a monolayer structure with 100% recycled content in direct contact with food—successfully passing stringent challenge and migration tests without the need for an ABA (virgin-recycled-virgin) structure. This innovation offers a true drop-in solution for injection molders and manufacturers.

The FDA’s No Objection Letter confirms that packaging made with UpSolv’s recycled resin meets the highest standards for food safety, material quality, and performance.

One of the key differentiators of UpSolv’s patented dissolution and purification process is its ability to selectively remove a wide range of contaminants—including solid residues such as labels and mixed plastics, as well as soluble substances like colorants, dyes, odors, and fillers—while preserving the functional additives required for high-performance applications. The process also restores the resin to a virgin-like state, enabling the production of new packaging and products with up to 100% recycled content. This offers a significant reduction in carbon footprint and supports circular economy goals.

About Polystyvert/ UpSolv

UpSolv (formely Polystyvert), offers the solution to make recycled plastics as cost-effective as virgin plastics and suitable for the needs of many industries. Thanks to a proprietary, flexible and highly optimized production process, it is now possible to manufacture a custom purified resin, offering the most advantageous recycling solution.

UpSolv offers the shortest recycling loop of high-quality thermoplastics recycling including polystyrene and ABS, serving industries such as packaging, construction, electronics, automotive, and toys. The technology is protected by more than 40 patents in 17 countries.

Media contact and information:

Virginie Bussières, Vice-president, External Affairs and Partnerships